Call Us: +1 307 262 8131

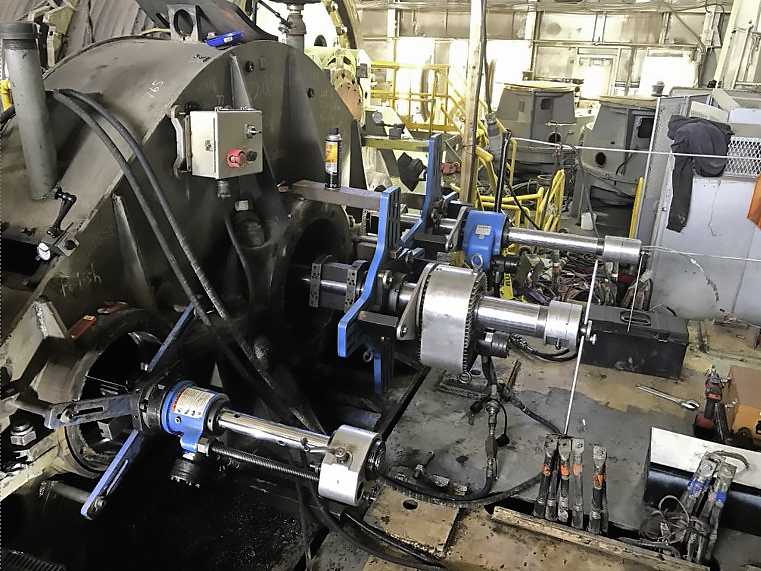

Mining shovels/dragline and equipment are most often repaired or serviced on-site. Whether the project requires machining, drilling, boring, welding, etc. HAMM Equipment has the consultants, work force, and specialized equipment available to handle all repairs, erections or relocations.

Designed with years of experience in the field, the HAMM lift system has successfully undecked hundreds of various shovel makes and models to provide customer’s successful rebuilds of swing systems and machining of critical surfaces. The system was built to optimize outages by allowing flexibility to keep the boom and dipper intact if no scheduled maintenance was planned.

Vital to the success of any shovel undecking is the assurance that critical dimensions are maintained or put back to OEM specifications. HAMM has designed and created their own purpose-built milling equipment to ensure satisfactory dimensional criteria is achieved through auditing and repair procedures.

With capabilities up to 5”, HAMM possess a variety of line boring and facing equipment to address rebuild needs as well as automated bore welding.

For lifting shovels to perform sideframe repairs & component exchanges, HAMM utilizes its climbing jacks to safety and securely lift the carbody. Four (4) Low pressure, 500 ton climbing jacks are used to synchronously lift a shovels carbody while cribbing is used to provide positive reinforcement so that the load is always supported.

The diesel powered hydraulic power supply is a skid mounted unit consisting of two identical systems connected in parallel. Originally used to drive oilfield casing, this VARCO pump along with its two 1000 ton jacking cylinders, have been used in several other applications including removing the tub of a Marion 8750 Dragline and lowering dragline booms.

HAMM utilizes the latest in optical technology to ensure rebuild quality and dimensional information is within specification.

With experience gained through managing large projects and delivering results, HAMM is available to consult on any of your core asset rebuilds. Through an innovative and cost sensitive approach, HAMM is fully capable of providing a value added strategies for major overhauls on your core loading equipment.